Making sense of all of your data from all of your projects can feel like trying to understand a foreign language. But, when we break it down into steps, it starts to make a lot more sense.

- News

Elevate Construction Projects with Schedule Oversight & Data Analytics

Managing complex construction projects is daunting due to the overwhelming number of moving parts to track and coordinate. That’s why the industry has used CPM Scheduling–which has been around for nearly half a century–because it is a powerful tool. With it, project teams have a roadmap, can identify critical paths, and optimize the use of resources.

Using analytics empowers project teams to gain valuable insights into project performance regarding risks and opportunities for improvement. With this information, you can take the initiative to keep your project on track and open the necessary lines of communication with stakeholders that increase the overall well-being of everyone involved.

One of the best ways to do this is to explore your project’s historical performance to create analytics, making the most of your CPM schedule data. Read on to dive into the power of schedule data analytics and discover how to elevate your project controls process.

The Best Data for Construction Projects

The most valuable lesson I learned from my 20 years as a construction consultant is that the best data in construction for understanding your project is data that your project already owns: schedule data.

Suppose you know how to take that information and make it speak differently. Doing so will help you understand progress, performance risks, delays, and inefficiencies in a manner that supports better outcomes through a project control process.

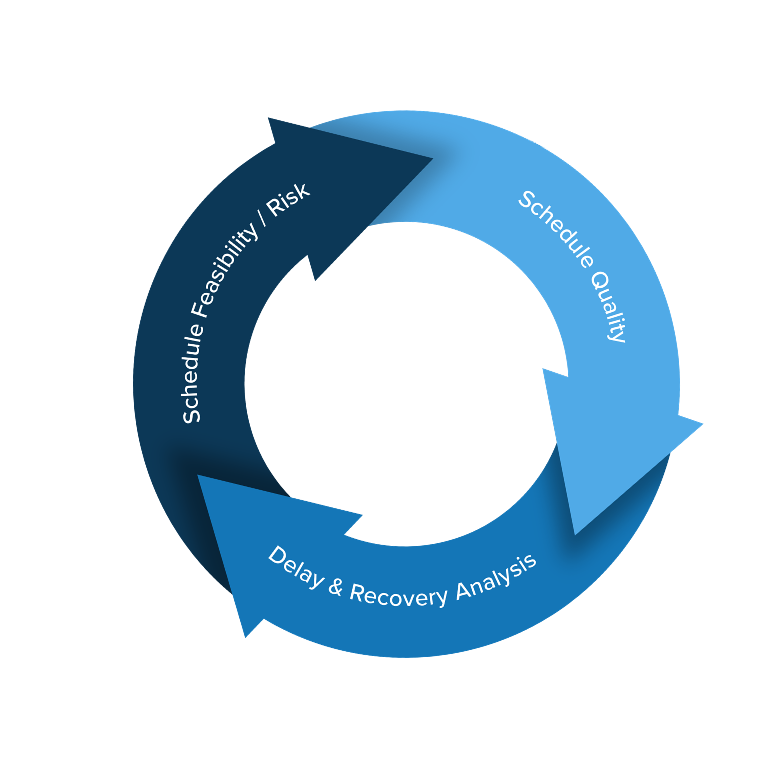

Having analyzed thousands of project schedules as a collective unit, I can tell you that the challenges arising on job sites across the globe are tied to this data. All this data forms a cyclical pattern that can be utilized for success.

Components of Successful Construction Analytics

Schedule Quality

Analyzing schedule quality ensures your project schedule is built well enough to manage a job. If your plan is created well and you experience a delay, you will know precisely where to react to restore balance. Without quality, the critical and near-critical paths are likely inaccurate, meaning you will put your resources in the wrong place in an attempt to recover, perpetuating the problem and extending the project lifecycle even further.

Schedule Delay

Throughout my career, I have seen schedulers make significant changes during the updating process without talking to the parties involved as frequently as they should. Deciding on shortening durations or removing logic ties without these discussions are the primary reasons why schedules and projects tend to go off course.

Not understanding why the delay moved the end date out does not solve the problem. Common project problems can be solved by thoroughly understanding how and why your project went off course, and that is done by looking at the historical delay data. Essentially, when a delay happens, the best thing to do is study them update-to-update, allowing for successful recovery and mitigation strategies to arise.

Schedule Recovery

Schedule delays happen, and schedule recovery is the response. Once you have experienced a delay and made changes, you must quantify them. Ask yourself:

- Are these good, intelligent changes?

- Are they being reflected in the field?

- Are the field teams hitting the proposed durations or modifying the plan?

It is vital to understand how you plan to recover to ensure you helping the project move forward, not just keeping a projected end date.

More often than not, the logical adjustments to the plan are overshadowed by all the other daily fires. Once the schedule gets submitted, many teams return to work without studying the necessary steps to keep up with the plan. Again, success in this category relies on having open lines of communication with everyone on site, especially those who are performing the labor.

Schedule Feasibility

After gauging schedule quality, delay, and recovery, you must question your schedule’s feasibility. If you are over-optimistic, your schedule is likely of low quality. And if you are not studying the delay or the recovery plan, you’re creating a recipe for disaster where nobody will know why the project isn’t close to being done, despite the estimated end date telling another story.

Additionally, schedule feasibility is crucial for the well-being of everyone involved. I know this from personal experience… Once upon a time, I worked on a beautiful airport project with hundreds of other professionals. It was one of the most remarkable buildings I have ever seen, but it never had a feasible, accurate, and trustable schedule. So, at the end of the project, everyone was fighting over money in a dispute. It was a disaster that nobody who worked on it ever wanted to speak of again.

It’s a pity that the memory of such an impressive construction endeavor was tarnished for those who contributed to its development; they deserved to take pride in that project. And that would have been possible with quality schedule submissions. We want projects to generate pleasant memories, resulting in future projects. This is all the more reason to treat this process as the cornerstone of accomplishing your project goals.

These Analyses Are Interdependent

Schedule quality, delay & recovery analysis, and schedule feasibility/risk work in an interdependent cycle. These items feed off one another; they can only be done with all of them being done together cyclically.

Quality is the linchpin of success, which opens up the door to performing a delay analysis that is accurate and understandable and a recovery analysis that is meaningful enough to manage toward an end date. Without schedule quality, there is no way to do an actual delay and recovery analysis because the critical path is off, meaning your schedule is also unfeasible.

Schedule Oversight: Analyzing Quality

When analyzing schedule quality, the focus areas should exceed the DCMA’s 14 points. While the DCMA methodology helps inform you of missing logic or long durations, I believe quality is more of a user’s preference.

This process involves a little bit of art and a little bit of science. It should circle around the preference based on the type of job and business operations at your company. You can create quality rubrics for different projects or points in time on a project, having metrics such as updating best practices or structural integrity. However, you must ensure that the information is accessible and visible across the organization.

Quality is all about metrics and risk thresholds that allow you to dive back in and “course correct.” Most importantly, it is about making this information visible to everyone involved so that the entire organization can understand the project and the risks involved in the project. And, if best practices are followed, risks pertaining to costs, resources, milestones, equipment, and time are all embedded in the schedule data. – no additional data is required.

Schedule Oversight: Analyzing Delay

Studying critical path delays over time is essential. Often, people receive a schedule update and focus solely on the end date. They believe the project is on track if the end date stays the same. Unfortunately, that is not the case.

You must analyze how far the end date is pushed out at every update period. You can do this by saving a “Status-Only” schedule update that shows you how far the end date pushed out from the previous period and how far it pushed out from the beginning of the job. This process contributes to conducting a “Half-Step Analysis” and allows you to keep track of the baseline, proceeding updates, and end-date variance. From there, you can see the extent of delays experienced and question how the critical path shifted.

Going back in time and looking at historical-critical and near-critical paths allows you to decipher which activities drove the job. You want to know the following for each period:

- What happened to the end date?

- How far was the project delayed?

- When was the project delayed?

- Were things done to try and recover against delay before the update period?

These things are best done in real-time, so you can highlight the historical-critical path, gauge delay, and discuss the impacts with the relevant parties at every update.

For instance, if the owner is delaying the job due to a change order, you can tell that because you analyzed it in real time. Then you can ask them what to do about it. Small requests for time are relatively straightforward; they are not supported only when these items are not discussed. When they are, odds are you will see more compliance and better, faster responses for collaborative recovery decision-making.

Schedule Oversight: Analyzing Recovery Through Changes

What should you do with the information gathered when analyzing schedule delays?

If you understand the delays and what’s being done to recover, you need to track the extent of schedule changes. And there are many ways a schedule can be changed, such as:

- Duration changes

- Calendar changes

- Logic changes

- Activity changes

- Critical and near-critical changes that alter the future critical path

Ask yourself:

- Were durations shortened?

- Was logic removed?

In doing so, you can reverse-engineer the thinking of the schedule changes, gaining further visibility on the thinking process to monitor whether or not the changes were followed through in real time.

Then, you must look at the future critical path and the accuracy of the schedule overall. This part starts getting into the feasibility of your plan, monitoring changes at every update to ensure you have your finger on the pulse of the critical path.

Studying Schedule Compression

Compression is one of the most valuable metrics to monitor from your schedule data. It tells you how much more work you are trying to cram into the schedule for the remaining job duration and how that information compares to the original baseline.

Anything over 20% compression is an issue because 20% compression means you plan to work weekends. If you are compressing more than that, it becomes a resource issue where your field teams are expected to work more than there is time in a day.

It is important to note that compression is not only about critical and near-critical activities. It involves all the work being pushed out because of float, meaning you have to think about how to mitigate compression effectively by discussing the schedule with the people in the field. Doing this at every update allows you to right the ship, force the compression number to go down, and get your project on track again. Otherwise, you will end up in a situation where you compress the schedule and relax the end date further than the previous delays.

That process is questionable because there is a need for discussions about changes as they can hijack the critical path. There are several questions you want to consider together with your teams that tell you a story about your project:

- What are the schedule changes?

- Why is the extent of changes being made?

- Are the changes related to delays?

- What changes surround the critical path?

- Are you being overly compressed?

Why Schedule Compression is Harmful

Overly compressing your schedule is the same as writing a check you cannot cash or kicking the can down the road. It’s misleading: to you, to the site team, to subcontractors, to owners, and to general contractors.

Furthermore, scheduling overtime results in decreases in productivity. H. Randolph Thomas, a noted American Society of Civil Engineers (ASCE) member, conducted a study regarding labor productivity’s effects when scheduled overtime was required. Many projects in construction and manufacturing were studied and showed a consistency of productivity loss when schedule overtime was utilized. That is what compression is; it results in trade stacking, asking them to stand on top of one another to get the job done, which amounts to poor productivity, losses, and a surprising amount of damage.

Having a compression process where you are responsibly looking at the extent of the impacts caused is how you end up with better results. Note that historical performance is an indicator of future performance. Adjust durations based on historical performance instead of compressing because if it wasn’t feasible in the past, it probably won’t be in the future. In essence, give yourself more time to complete activities than initially planned. Then, go into the field and work hard to push the end date back rather than making an unfeasible, unreliable schedule.

What to Know About (Critical Path) Delay Analysis

In short, delay analysis is about identifying the driving factors (or “historical-critical path”) that impact the end date and result in extended general conditions or loss of revenue. Most delay damages occur when the end date of a project is pushed out and consist of:

- Extended General Conditions Cost (contractor)

- Loss of Revenue (owner)

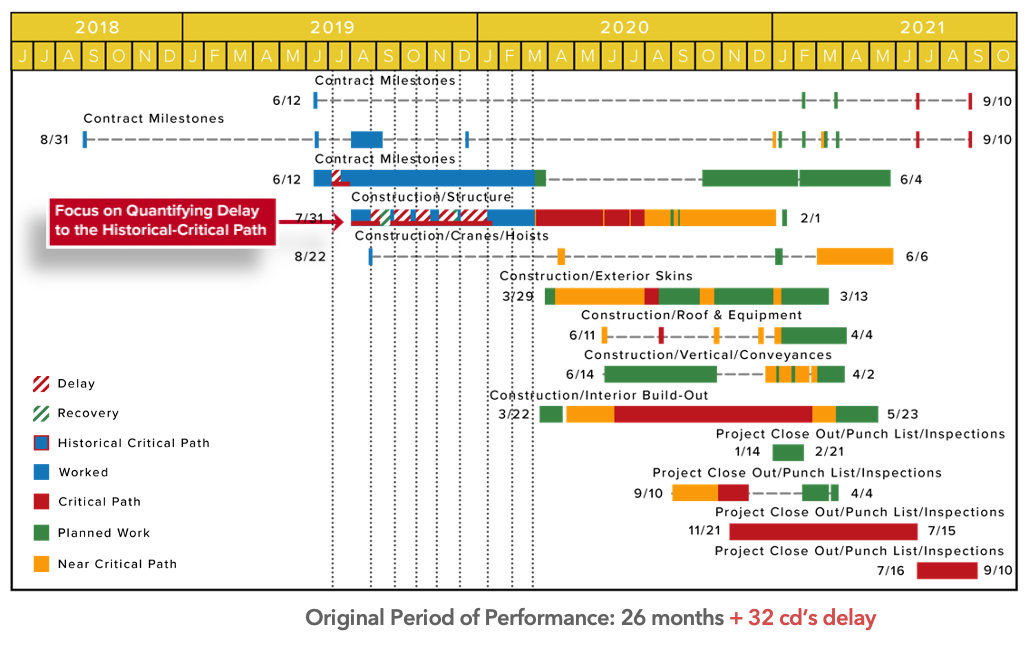

Delays to the critical path are the only thing that can delay an end date. And without having a high-quality schedule, the arguments surrounding delay are infinite because the critical path becomes arguable. The more schedules utilized in delay analysis, the better because they will provide visibility into the changes and other decisions made along the way. Let’s look at some schedules to visualize this process:

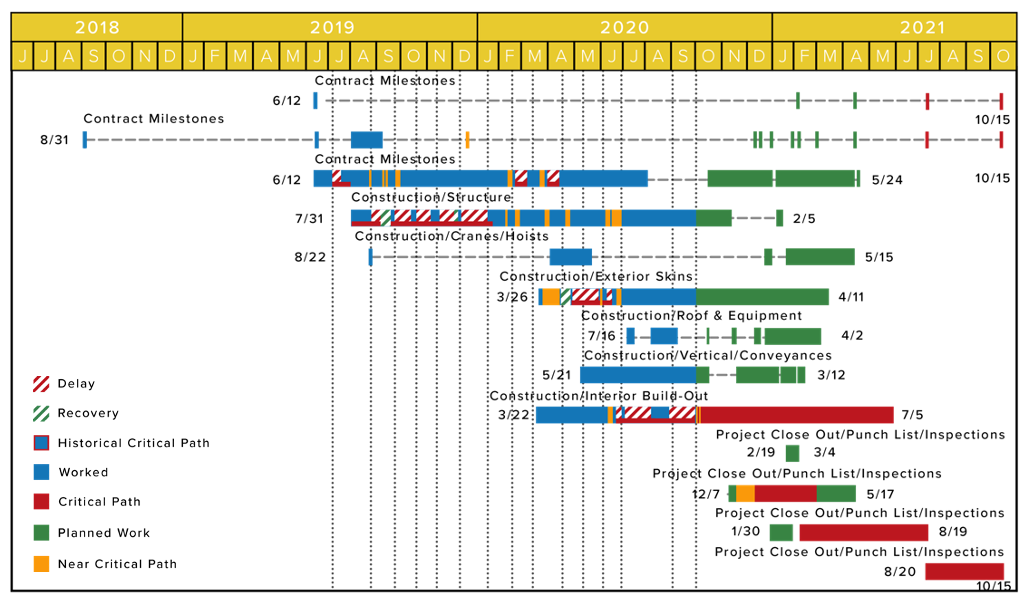

Delay Analysis Example: Baseline Schedule

Schedule Update #6

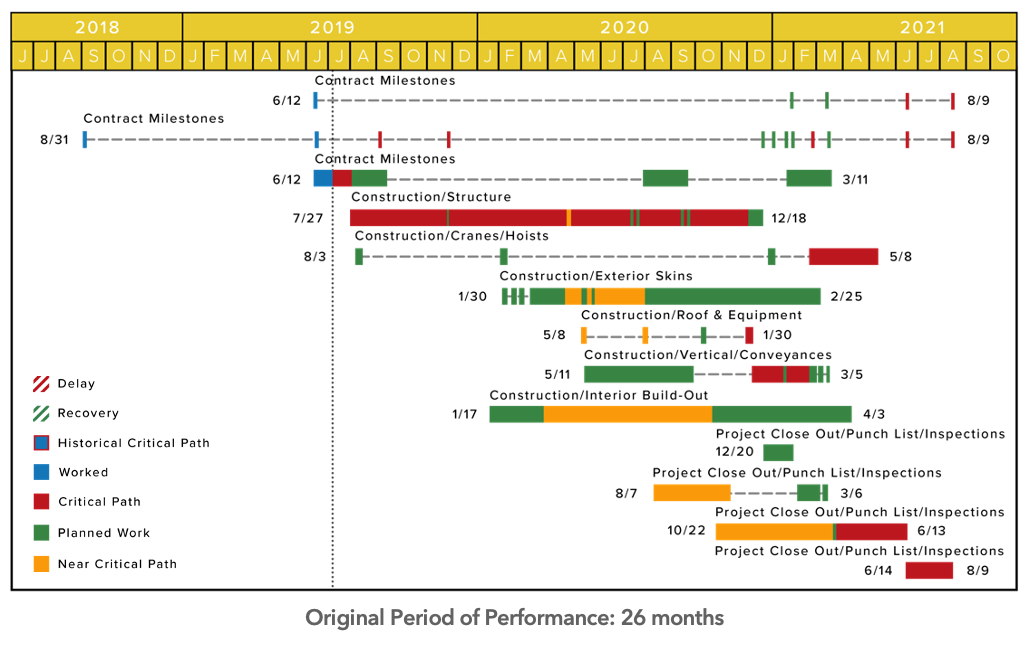

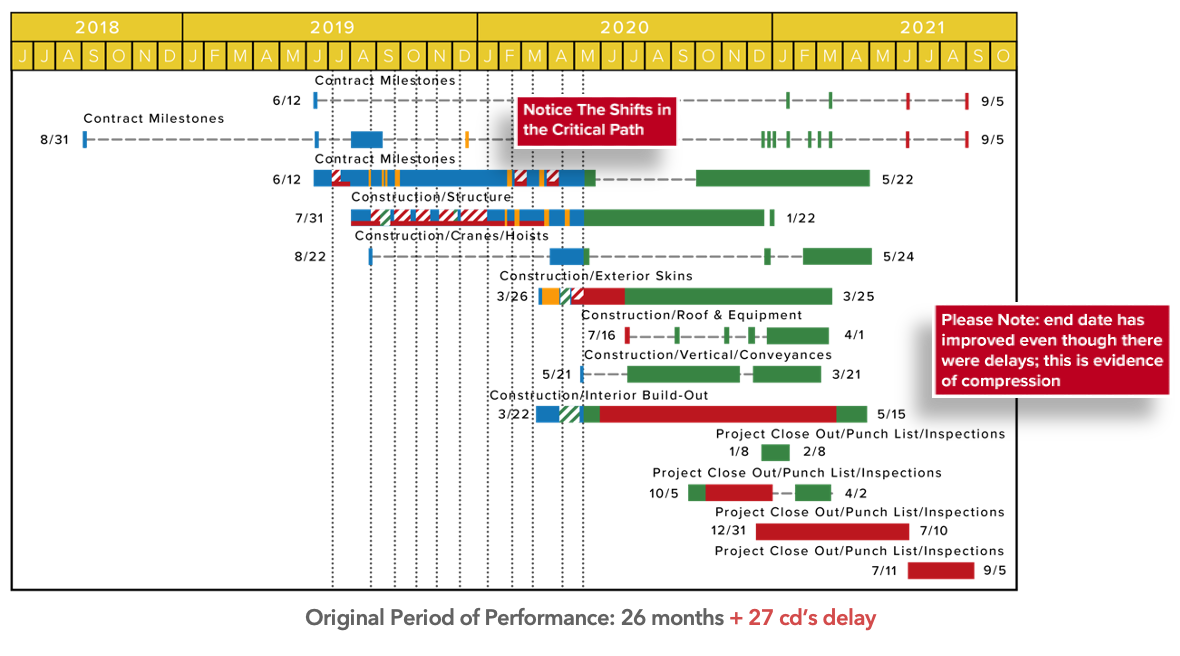

Delay Analysis Example: Schedule Update #8

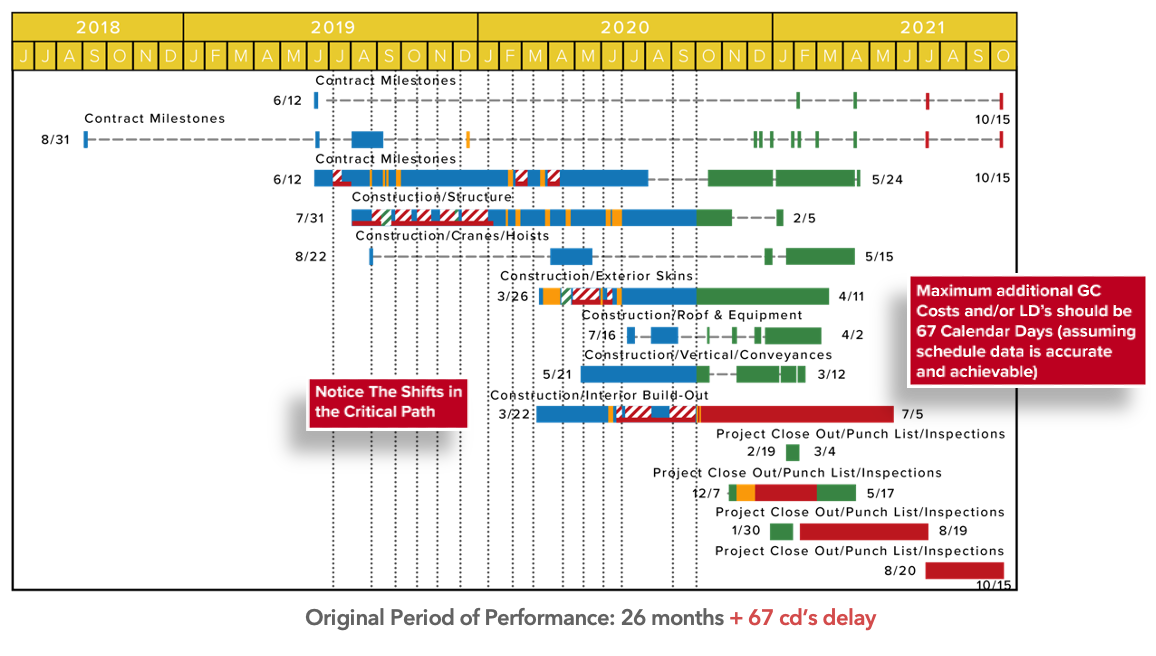

Schedule Update #10

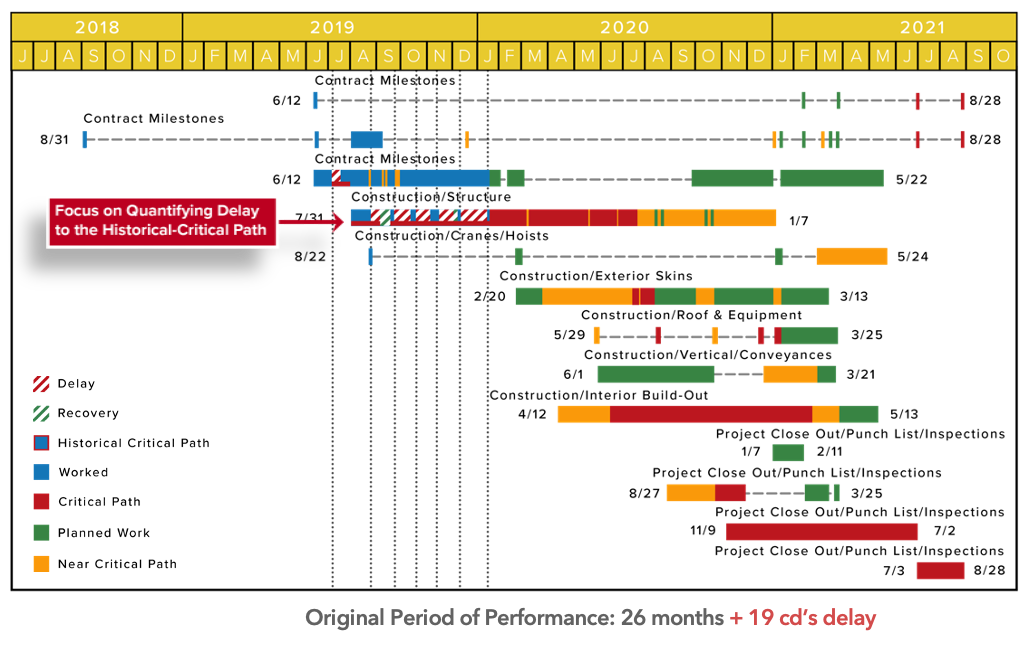

Delay Analysis Example: Schedule Update #14

Notice the shifts in the critical path and the lack of end-date variance from update to update. If the end date does not move even though delays happened, that indicates schedule compression and reveals a pattern of changes made to mitigate critical-path delay.

Your schedule is a calculator. Additionally, you can use your schedule for analysis to support better outcomes, otherwise known as implementing a project controls process.

Key Takeaways: CPM Schedule Oversight and Analytics

- CPM lays out work plans, using “float” to prioritize work based on the risk of delaying the end date.

- CPM schedules (baseline and updates) must maintain a high standard of integrity and quality to be effective.

- Schedule changes are inevitable but should be nominal to minimize risk.

- Delay damages should be quantified based on impacts to the project end date, not interim milestones.

- The industry needs improvement in the scheduling department, starting with across-the-board, thorough understanding.

These items support project controls. Project controls are about taking schedule data information and analyzing it in a manner that promotes better outcomes. But if you don’t have time or don’t know how to do it, you will continue to end up in a place where your project is overly compressed, and delays happen, but you don’t know why. That is what I want to help you avoid. I want to institute change to get to a place where projects are very predictable.

Luckily, you have that information at your disposal to accomplish what you want and get your projects done on time, on budget, and never end up in court. All of this is possible, and the technology is here. It just needs to be understood, studied, and learned. If you’d like to unlock the capabilities of automated project controls, fill out the form below and I’d be happy to walk you through it.

RELATED STORIES

Making Construction Data Analytics Easier to Understand

Making sense of all of your data from all of your projects can feel like trying to understand a foreign language. But, when we break it down into steps, it starts to make a lot more sense.

Overcoming Confirmation Bias in Construction Project Management

Confirmation bias can be particularly problematic in project and schedule management, where decisions must be based on accurate and comprehensive information.

Top Construction Scheduling Software in 2023

SmartPM’s recognition as a top construction scheduling software in 2023 attests to the immense value in automated project controls.

Putting the ‘Smart’ in Project Management with Project Controls

Project controls are not just a subset of project management; they are its backbone, focusing on meticulous monitoring and analysis.